MOQ:10 pairs

Price:USD50~500/pair

Standard Packaging: STANDARD SEA WORTHY PACKAGE

Delivery Period:10days

Supply Capacity:300pairs/month

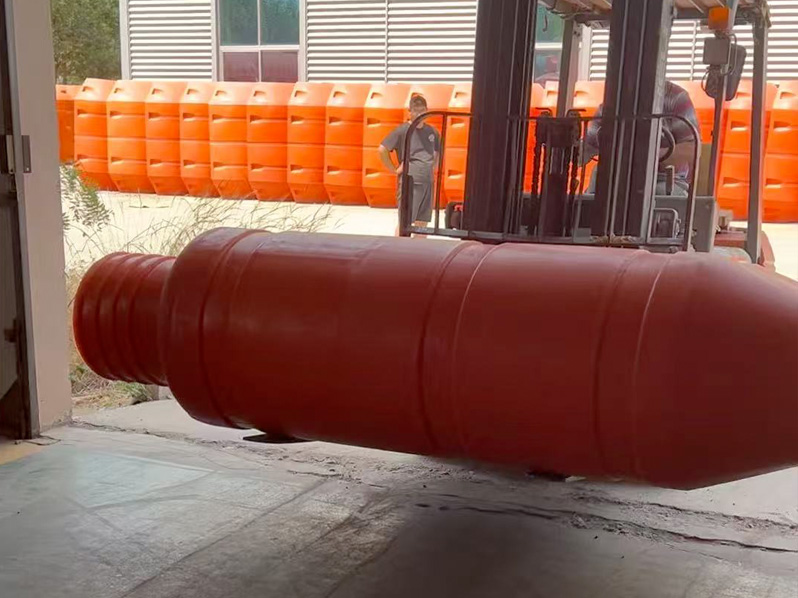

1. Good flexibility, excellent impact resistance, especially suitable for deep water construction;

2. Easy to install and use, low moving costs;

3. Higher corrosion resistance, longer service life, three times longer than steel floats;

4. Cheaper, cost performance is better than steel floats.

1. Used in sand dredging pipelines;

2. Can be used in dredgers, dredgers, etc. in the sea, lake or river;

3. Specially used for laying water lines for dredging projects.

a. High Corrosion Resistance

HDPE material structure is saturated molecular group, with great chemical stability,good resistance of various corrosion mediums(acid,alkali,salt)and organic solvents.

b. High Impact Resistance

c. High Pressure Resistance

d. Environment Proctection

The manufacturing and processing of wear resistant HDPE pipe is low carbon,without wasted water,exhausted gas and waste residue,which saves 20% energy compare with the traditional steel pipes.

e. High Flexibility

f. Non-scaling

g. Low energy consumption

| Structure | Floater |

| Service Life | More Than 15 Years |

| Application | Dredging, Marine Engineering, Offshore Oil And Gas, Etc. |

| Float Size | Customer Made |

| Product Category | HDPE Pipe Floater |

| Characteristic | Size Range: 110mm to 1150, Buoyancy: 150 kgs to 6500kgs |

| Material | High-density Polyethylene (HDPE) |

| Package | Standard |

| Lifetime | Long |

| Installation | Hot Galvanised Steel Bolts And Nuts |

Float colors and sizes can be customized, with commonly used float colors being yellow and orange.